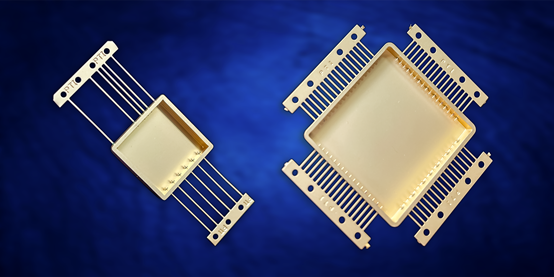

2024 年 2 月 15 日,射频、微波和毫米波设备高频和高功率半导体封装设计、生产和组装领域的领导者StratEdge Corporation宣布其具有制造混合封装的能力,用于难以或不可能重新设计的传统应用。这些混合封装通常是几十年前开发的,在许多关键的国防应用中仍然至关重要。

StratEdge 擅长生产带有密封馈通的大型金属外壳所需的玻璃与金属、陶瓷与金属和金属与金属密封技术。与模压陶瓷封装类似,ASTM F15 合金是构建混合封装的关键成分。StratEdge 拥有多台各种气体气氛的炉子,用于玻璃密封以及钎焊或钎焊各种成分的组件,包括金属化陶瓷、铁合金、铜、铜复合材料和铜层压板。

StratEdge 全球销售副总裁 Casey Krawiec 表示:"StratEdge 拥有独特的设备和专业知识,可以制造这些类型的封装,制造模压陶瓷封装的工艺与制造军事和航天应用中使用的传统混合封装的要求有许多相似之处。"

英文稿原文:

Santee, Calif. – 15 February 2024 – StratEdge Corporation, leader in the design, production, and assembly of high-frequency and high-power semiconductor packages for RF, microwave, and millimeter-wave devices, announces its capabilities for making hybrid packages used in legacy applications where redesigns are difficult or impossible. These hybrid packages, often developed decades ago, are still vital in many critical defense applications.

StratEdge excels at glass-to-metal, ceramic-to-metal, and metal-to-metal sealing technologies necessary for the production of large metal housing with hermetic feedthroughs. Similar to its molded ceramic packages, ASTM F15 alloy is a key component used in constructing hybrid packages. StratEdge possesses numerous furnaces with various gas atmospheres that are required for glass sealing and brazing or soldering components of various compositions including metalized ceramic, iron alloys, copper, copper composites, and copper laminates.

"StratEdge has the unique equipment and expertise required to build these types of packages," says Casey Krawiec, VP of Global Sales for StratEdge. Krawiec further explained, "Our processes for manufacturing molded ceramic packages share many similarities with the requirements for building legacy hybrid packages used in military and space applications."

长按识别二维码关注公众号,点击下方菜单栏左侧“微信群”,申请加入交流群。