传统的纳米注塑,需要进行表面处理,同时对金属,塑料性能,模具结构,注塑参数有很高的要求。日本宝理开发了一种Quick-10 技术,无需表面处理即可让塑料和金属有效的连接一起,这种技术利用对金属嵌件快速的升温和降温,仅在注塑过程中就能够完成塑胶和金属的粘接。宝理已经开发可以用于Quick-10 技术的PBT,和PPS。

Engineering thermoplastics supplier Polyplastics has developed a technology that improves metal-plastic bonding of composite parts for the automotive and electrical/electronics industries without the need for pre-treatment of the metal inserts.

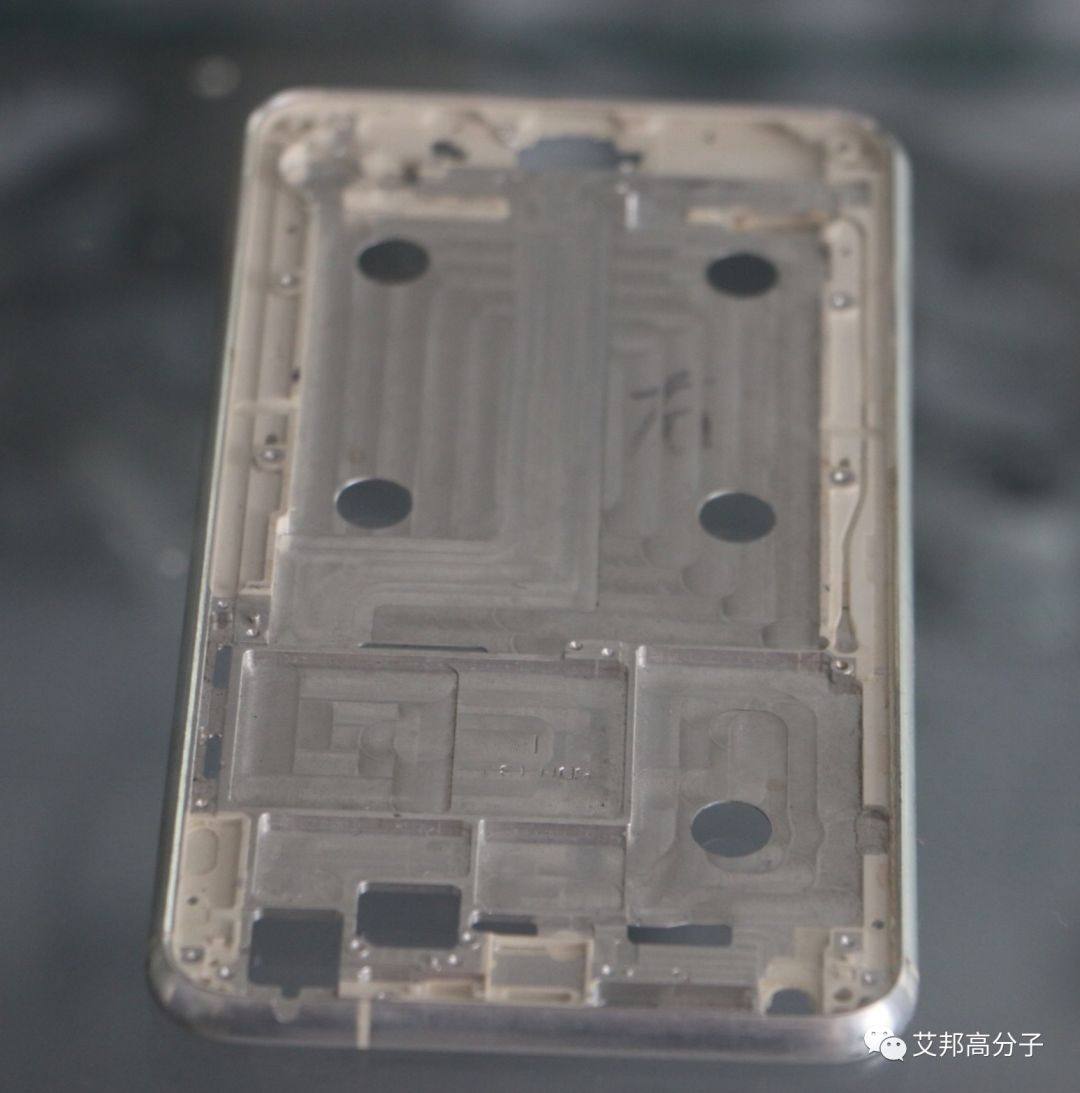

Polyplastics’ Quick-10 metal-plastic bonding technology has been used in mobile device parts (mobile phones, tablets, digital cameras) and some auto-related parts.

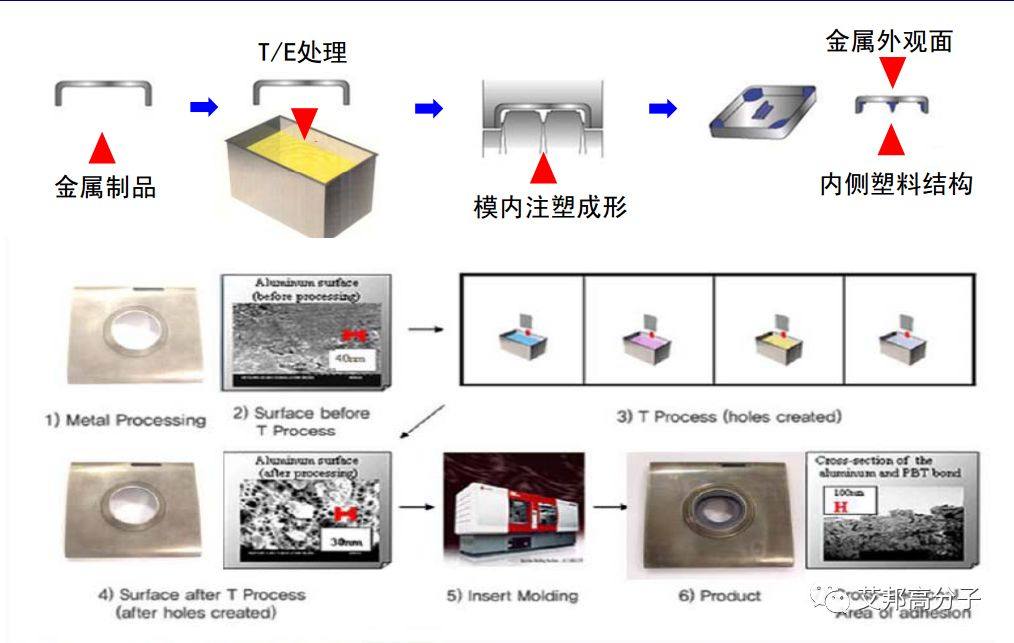

Direct metal-plastic bonding is a process which typically employs metal insert molding. In the traditional process, metal inserts and plastics are firmly bonded via introduction of molten plastic through injection molding to metal inserts which have already undergone appropriate surface treatment. These metal-plastic composites combine the properties of metals (high rigidity, electrical conductivity) and engineering plastics (low density, electrical insulation). However, while numerous factors (metal inserts, plastics, mold structure, injection molding parameters, etc.) generally have adverse effects and prevent stable bonding, Polyplastics has made progress with successful bonding through its Quick-10 technology.

The Quick-10 process usesrapid heating and cooling of metal inserts to realize direct metal-plastic bonding through the injection molding process alone, without any special surface treatment for the metal.The plastics employed must, however exhibit properties such as interface affinity, surface transferability (flowability), and low shrinkage to realize good bonding. To this end, Polyplastics has developed appropriate polyphenylene sulfide (PPS) and polybutylene terephthalate (PBT) grades for the process

The Quick-10 process uses rapid heating and cooling of metal inserts to realize direct metal-plastic bonding through the injection molding process alone, without any special surface treatment for the metal. The plastics employed must, however exhibit properties such as interface affinity, surface transferability (flowability), and low shrinkage to realize good bonding. To this end, Polyplastics has developed appropriate polyphenylene sulfide (PPS) and polybutylene terephthalate (PBT) grades for the process

补充资料:

日本大成塑料(Taiseiplas)株式会社于2002年发明了纳米成型技术(NMT)。大成第一个字母为T,所以命名T处理。我国研究人员改变了纳米孔形成方式,衍生了不同的处理方法,其中,在通电的情况下进行的处理方法被称为E处理,字母E是电的缩写

图:纳米注塑工艺最重要的应用:手机金属结构件与塑胶结合

本文英文来源:

Metal-plastic bonding technology developed for automotive and electrical/electronics

by:

Stephen Moore

Automotive and Mobility

Materials & Assembly,Consumer Electronics,Injection Molding,Materials

May 21, 2018

| 欢迎长按二维码,加入艾邦塑胶手机外壳群,备注 “IMT”,和专业的人士进行交流。 |

活动推荐:作为仿玻璃的重点工艺,2.5D /3D复合板材,IMT将在今年下半年和明年快速放量,6月30日我们举行塑胶外壳论坛:

第二届手机塑胶外壳(IMT、复合板材)技术与应用论坛

5G时代,塑胶重生

2018 年6 月30 日深圳观澜格兰云天酒店

主要议题:

序 | 演讲议题 | 演讲人 |

1 | IMT在手机中的应用 | 征集中 |

2 | IMT薄膜设计 | 征集中 |

3 | 手机装饰纹理趋势 | 征集中 |

4 | IMT自动化工艺实现 | 东莞市力超精密机械有限公司 |

5 | 手机中框IMT专用材料介绍 | 中塑新材料 |

6 | 高压空气成型复合盖板最新动态 | 东莞市新桥联复合材料科技有限公司 |

7 | 3d喷涂防指纹加硬工艺全方案 | 深圳市智宇材料科技有限公司 |

8 | PVD镀膜的效率以及良率提升方案 | 姚强 |

9 | 高压复合板材的最新进展 | 东莞市震宇模具塑胶实业有限公司 |

10 | 塑胶外壳相关新工艺,新设备 | 拟邀请群达塑胶电子(深圳)有限公司 |

11 | 2.5D与3D复合板材的材料选择与应用 | 四川龙华光电薄膜股份有限公司 |

12 | uv转印材料与纹理设计 | 惠州市德佑威电子材料有限公司 |

报名链接:

方式1:在线登记报名;

方式2:请加微信并发名片报名;

邓小姐:15817337805,微信同电话号码

江先生:18666186648,微信同电话号码。

阅读原文,即可报名

始发于微信公众号: 艾邦高分子